NQE was engaged by Ausdraulics to reverse engineer and design a custom spline coupling for the LARC-V (Lighter, Amphibious Resupply, Cargo, 5 ton) vehicles in the defence force.

In reviewing the original spline several issues were identified; mount changes had occurred over the years, incomplete spline engagement was apparent, differing splines with incorrect fit, the driven spline was supported by bearings that were inadequate for the increased load capacity and required design life.

The new spline was designed to transmit power from a V8 diesel engine producing 370hp and 884Nm torque through a power take off unit (PTO) to two hydraulic pumps. As part of the upgrade one of the hydraulic pumps was being increased in capacity to facilitate the demand of the hydraulic bilge pumps and steering system.

No drawings were available for the arrangement so detailed measurements were taken to reverse engineer the part. Detailed torque and stress calculations were completed in accordance with the recommendations by ANSI and SAE to determine the required materials, dimensional conformity, grade and expected design life.

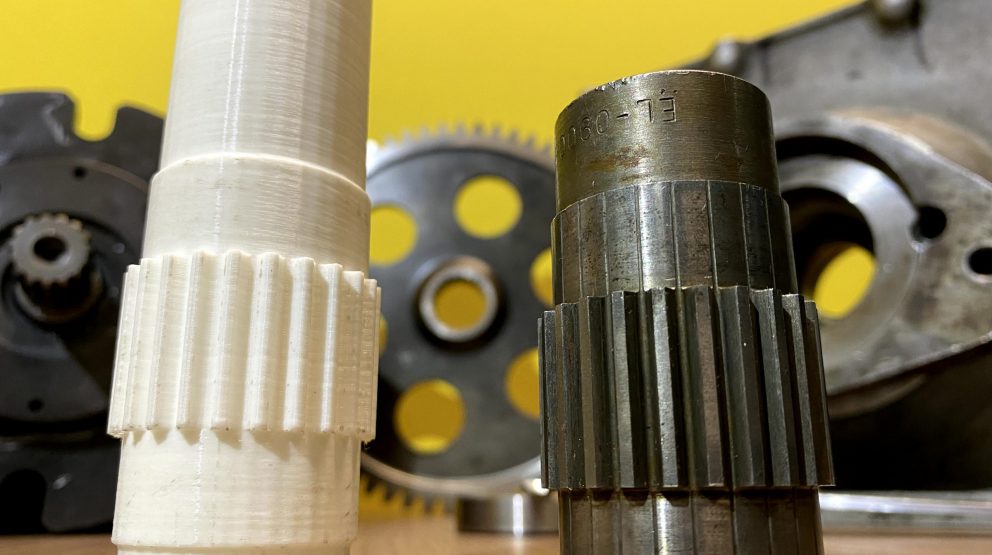

The part was 3d printed to review the final fit using accurate 3d modelling. The part was then assembled with the drive unit and measurements were taken to ensure complete engagement of all splines was occurring.

The final steel part was designed and will be manufactured utilising high strength steel grades and case hardening, dimensional tolerance and finite design life specified by North Queensland Engineering.

NQE can design and 3D print parts in PLA, ABS, TPU and Nylon and other filaments requiring fully enclosed chambers with heated beds and nozzle temperatures up to 300°C.

3d printed part with the original components